BW-603V3

- Product Specification

- Category: Hot Cold Basin Mixer

- Height: 120mm

- Flowrate: 7-24 Lpm

- Working pressure: 0.1 – 0.5 MPa

- Working Temperature: 4 - 90°C

- Color: Metallic Chrome

- Possessing the nickel plated thickness of over 8 micrometers and a chrome plated thickness of over 0.25 micrometer, which is up to the 24-hour standard of ASS test with the long lighting duration, high quality and convenience both in cleaning and maintaining.

- Raw materials: First grade vacuum-plated copper which is safe for human wellbeing.

- Hot and cold mixer with easy controlled handle.

- A ceramic core cartridge with high durability (Ф 35 millimeters) can prevent water from leakage in every condition of water pressure, from low to high.

- Using Air Power technology to mix the natural air with water to create strong steady and melodious steam flows.

- Having a modern design with solid and easy-to-clean structure.

- Plating warranty: 5 years

- Nickel and chrome plated copper mixer body and durable ceramic cartridge: 1 set

- Chrome-plated copper decorative cap: 2 pieces

- Fixation set: Stainless steel 304 screw, brass nut and rubber gasket: 1 set

- Pop up waste and drainage pipe: 1 set

- User manual and technical drawings: 1 set

- Guarantee card: 1 set

AMAZING DURABILITY

Ceramic core cartridge is designed to suit with the water condition in Vietnam, being anti-corrosive, anti-aging, capable with high temperature and high pressure (up to 16 bars), and having a long lasting lifetime.

HIGH ACCURACY PROCESSING TECHNOLOGY

FULLY AUTOMATED PLATING SYSTEM

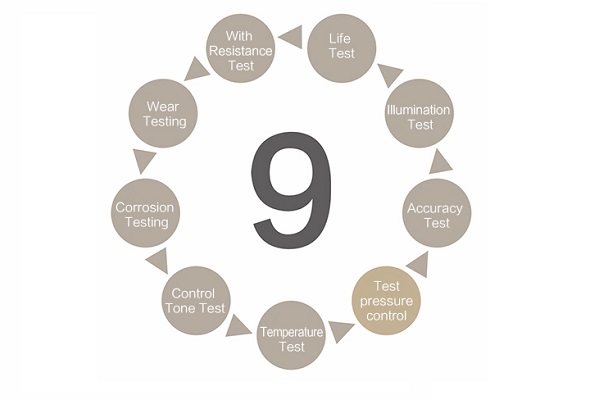

WELL CONTROLED QA & QC PROCESS

As a result, each product can keeps its long lasting shining look, without any signs of being corroded, being rusty or peeled off, even in the most extreme conditions (i.e. from -30oC to 90oC or in 5% salt solution with 200 consecutive hours)